Experts from member companies are working together

in international teams

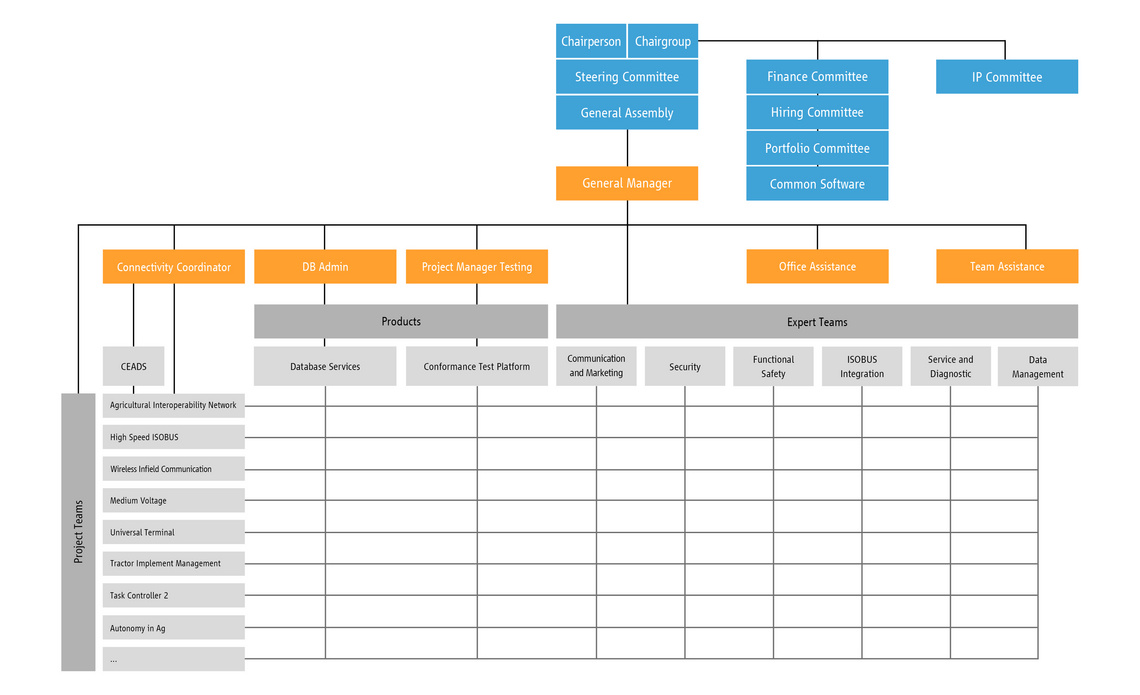

Eight expert teams supports the AEF organisation with information about new technology trends, new standards and regulations. Team members propose projects which promote ISOBUS related topics and new technologies that guarantee compatibilty in the market. This could also include connectivity and data exchange between different manufacturers. AEF projects are organised in voluntary teams supported by members of the expert teams when required. By working in this way the AEF has evolved to a matrix organisation structure.

Expert Teams

Communicate the current status and results of ongoing AEF activities to members and the public. This includes activities needed for conferences, press releases, trade shows as well as Corporate Design.

Responsible for the development and maintenance of the AEF Conformance Test tool to the ISO 11783 standard. This activity is fundamental to support the AEF ISOBUS Database and the information there in, used by members, dealers and end users.

The AEF ISOBUS Database is fundamental to the AEF, as the repository for ISOBUS products which have passed the AEF Conformance Test.

This team takes care for all use cases relating to existing standards, develops updates and is the point of contact within the AEF for all questions relating to data transfer to the farmer's/contractor's office, via future-oriented hubs/clouds in a wireless way or also via existing data carriers.

The team of those experts supports project teams who are looking for suggestions on the topics of data transfer, data synchronization or fundamental FMIS issues.

Development of application guidelines related to functional safety issues outlined in directives and standards used by all manufacturers of agricultural machinery (e.g. ISO/DIS 25119 and ISO 15077).

Provide clear implementation guidelines for members to develop specifications for future ISOBUS technology based on common implementations of the technology.

Service experts collaborate to provide quick and efficient ISOBUS support on fault and troubleshooting issues. Diagnostic experts will provide guidelines and methods to diagnose ISOBUS functionalities via standardized interfaces.

Address the organization's need for a strategic approach to security. The AEF needs to ensure that all information and technology it provides to members and the public provides a high level of security that can be relied on.

Projects

The AEF Agricultural Interoperability Network AgIN is the next step into the harmonization of the digital ag world by AEF. Driven by the aims of AEF TIM and ISOBUS AgIN's ultimate goal is to create an interoperability solution for ag online platforms. It will enable providers of digital ag services to interconnect on a trustful high-quality basis and leveraging existing AEF solutions in an even more synergetic matter for the digital business.

The main goal is the definition of a holistic approach to autonomous agriculture, prioritizing operator ease of use. The team will focus upon the modification of existing standards and AEF guidelines along with the creation of new standards or guidelines where necessary. As with other AEF projects, interoperability between various manufacturers will be a core requirement of the project.

The mission of DCS is to provide a new functionality to enable plug-and-play, off-the-shelf video solutions that offer vision system component interoperability and easy integration for manufacturers and aftermarket sales in the context of HSI infrastructure. The work covers the development of a new AEF guideline for software and hardware in cameras and terminals.

This project aims to develop a High Speed ISOBUS communication network to enhance bandwidth and reduce latency. It will define system architecture, hardware specifications (ECU interfaces, cables, connectors), and the communication protocol for initial use cases, including “command and control” and “digital camera systems.” Extended use cases involve connectivity for machine-to-machine communication. The HSI project is also moving toward ISO standardization to address the needs of various sectors like Agriculture, Construction, and Mining, promoting economies of scale. While standardization focuses on commonalities, the AEF prioritizes agricultural use cases for a smooth transition from ISOBUS to HSI.

INFO will close this gap by collecting useful information directly out of an ISOBUS system. It will be visible to the operator and furthermore, there will be a way to transfer the information into a standardized way.

AEF INFO is driven by three main use cases:

What are the ISOBUS functionalities and capabilities of my machine?

What is the right product (e.g. a baler) for the customer?

Why is the system not working as expected?

Draw up guidelines for the medium voltage range, both for the technical requirements (voltage, current, power) and for the connector. The team members are benefitting from their experience gathered in the High Voltage project.

The aim of this project is to develop and release the next generation of the Task Controller. TC2 will include the latest revision of the ISO 11783 part 10 standard for ISOBUS Task Controllers, along with many clarifications. Additionally, new AEF guidelines will be developed, and an AEF Conformance Test environment will be created for all functionalities of TC2.

The work of this project is to extend and develop the release guideline for the next generation of Tractor Implement Management. In addition to the new guideline, the AEF conformance test tool for TIM will be updated as well to reflect the new features in the new generation on TIM.

The work of this project is to develop and release a guideline for Universal Terminal generation 3. This guideline would then allow the AEF Conformance Test to be updated to test the universal terminals on the market which have been designed according to the latest release of ISO 11783 part 6.

Wireless Infield Communication is developing interoperable machine-to-machine communication using global radio standards with a range of up to 2 km (appr. 1,25miles). This will support various use cases, including sharing coverage data, providing guidance lines, and enabling remote machine control like platooning in unloading scenarios with harvesters and transport vehicles. The team also aims to enable wireless video stream sharing and integrate agricultural machines into the C-ITS ecosystem for enhanced safety and efficiency. All functionalities will be implemented securely through a common software solution for seamless integration into OEM vehicle projects.

Employees are welcome

Employees from member companies are welcome to engage in one or more teams.

Participation is voluntary, however, the AEF’s progress depends on actively engaged members.